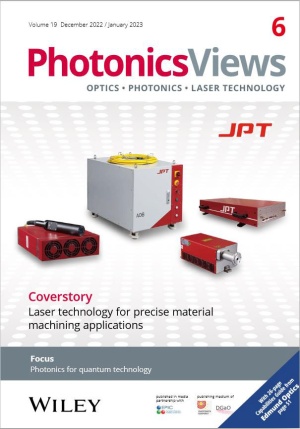

Shenzhen JPT Opto-electronics focuses on the development of various laser sources, such as MOPA fiber lasers, DPSS lasers, ultrafast lasers and cw fiber lasers p. 46

Ausgabe lesen

Shenzhen JPT Opto-electronics focuses on the development of various laser sources, such as MOPA fiber lasers, DPSS lasers, ultrafast lasers and cw fiber lasers p. 46

EPIC's photonics technology manager Ivan Nikitskiy talks to Mostafa Afgani, CTO and co-founder at PureLiFi, a developer and innovator of Li-Fi technology.

Shrouded in myths, powerful and sensitive: Prof Jens Eisert, physicist at the Freie Universität Berlin, explains how quantum computers work and how far their development has progressed.

Michael Förtsch, Tobias M. Wintermantel

More than thirty billion dollars has gone into funding quantum technologies, and much of this money has been allocated to quantum computing projects. Accordingly, a large number of different realizations for quantum computing are being developed. The photonic approach is one of the most promising of these ideas because it is based on well-known materials, established production processes, and operation at room temperature.

Current infrared (IR) sensing and imaging technology is at its practical limit. Siliconbased CMOS solutions are cost-effective but spectrally limited, while InGaAs sensors offer excellent photon conversion efficiency, but are too complex and costly. As the world experiences both a second quantum revolution and an increasing proliferation of machine sensing technology, using quantum dots to gather detailed IR data is the next frontier for sensing and imaging technology

Patrizia Krok, Malcolm Simpson

In quantum applications such as optical clocks ultrastable laser sources address extremely narrow atomic transitions without introducing noise to the system. This level of stability and precision has historically only been achieved under controlled laboratory conditions. Novel commercial solutions combined with new approaches are now meeting the high demands for field applications of emerging quantum technologies.

In recent years, driven by the need for energy conservation and pollution reduction to develop a sustainable society, the building-integrated photovoltaics (BIPV), centralized photovoltaic power stations and new energy vehicle markets have grown significantly and with that increased the demand for glass that requires more precise micromachining methods.

Regardless of the type of laser, all can produce biological effects on the human body if protective eyewear is not used. Many lasers produce a beam of light in the UV or infrared spectrum that our eyes are not able to detect. To qualify as laser-protective eyewear, independent laboratory tests validate and certify the protective capabilities and optical density (OD) against the standard, using the actual laser, including performing destructive testing. This certification is required to meet standards like European norm CE EN207 and American National Standard for Safe Use of Lasers ANSI Z136.

Diode lasers, even those of low to medium power, need to be cooled – not only to avoid thermal damage, but also to keep their temperature-dependent output wavelength as constant as possible. Compressor-based cooling systems are well suited for medium to high-power lasers, but they are usually large, loud, and generate vibrations. However, there are also compact, quiet, and low-vibration solutions.

“The filter lifetimes have increased enormously. For us, this means greatly reduced effort and, most importantly, costs,” says Olaf Lehmann, head of production at Werba Plast.

Successful implementation of a motion system involves more than just the purchase of modern positioning tables and control systems. The correct design of the machine structure, measuring system and mounting are all essential considerations. Environmental factors such as temperature, cleanliness, vibration, acoustics and EMI (electromagnetic interference) also have an influence.

Until recently, controlling the motion path of lasers across multiple axes has come with certain limitations in performance, speed, practicalities and, on top, higher complexity and costs. With the development of new modular controllers, flexible solutions that enable a laser to be combined with multiaxis positioning are making it easier for system integrators to design and build advanced systems for a new era of laser applications.